|

Dredging crews began construction on the ship canal and turning basin. It would be used by the ore boats that would haul iron ore, limestone, and other materials.

|

The Grand Calumet River was moved. Shifting sands made the task difficult, but company engineers and workers completed the project.

|

|

A dock wall, nearly a mile long, was constructed to provide a storage area for ore, limestone, and needed materials.

|

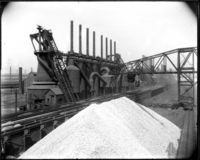

West of the docks, sites for the blast furnaces were set aside. Pictured is the area for furnaces one through four.

|

|

Stoves were constructed for each furnace to provide the blasts of heat necessary to make iron.

|

Specially built unloaders were put into place to empty the ore boats that brought ore from Minnesota or Upper Michigan.

|

|

Since conveyor belts were not practical at the time, huge bridges scooped up the materials and emptied their loads near the blast furnaces. The massive structures ran on rails along the furnace line.

|

West of the furnaces, Open Hearth furnaces would be needed to make ingots. Each structure had dozens of smaller furnaces. Ingots would move west to the finishing mills.

|

|

Near the Main Gate along Broadway was the main office. Still in operation today, it contains the various departments that handled daily operations of the Big Mill.

|

The basic steel process ran from east to west as materials moved from one facility to the next. At the Coke Plant coal was specially heated in ovens to make coke, a basic ingredient needed for the blast furnaces.

|

|

The Elgin, Joliet and Eastern Railroads moved material throughout the mill. Coke to the blast furnaces, molten iron to the Open Hearths, ingots to the finishing mills were moved by rail.

|

U.S. Steel ore boats brought in ore and limestone throughout the year. Pictured is the Elbert H. Gary, the first ship that entered the plant when production began in 1908.

|

|

Once the mill was in operation, the skyline along Gary's lakefront was not one of office towers and parks. Instead it was a tribute to the huge, powerful, blast furnaces.

|

Blast furnace gas provided the heat for the blast furnace stoves. Pictured is the main line which ran to the Power and Fuel Department, then to each furnace.

|

|

Alongside each furnace was a cast house. Workers drilled into a special area of the furnace wall when the iron was ready. Molten iron then ran into special rail cars for shipment to the Open Hearths. It was a dangerous procedure carried out every shift.

|

Molten slag was not used, but dumped north of the blast furnaces.

|

|

In the Open Hearths the steel process continued. Like the blast furnace area, workers took part in a dangerous job that called for a high state of alert.

|

At the #2 Open Hearth molten iron is poured to make the ingots.

|

|

Steel rails were produced at U.S. Steel's Gary Works, The operation came to an end in the 1980's.

|

At the Merchant Mill, finished products were shipped to steel-related firms in the Midwest.

|

|

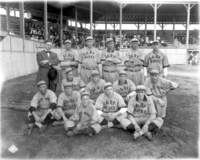

A typical crew at the Merchant Mill. Safety gear was not yet provided to workers.

|

Most early steel companies did not provide any wash-house facilities. Pictured are temporary showers before 1914.

|

|

To care for injured workers, the Gary steel plant had its own hospital. The building, east of Broadway, serves as an office today.

|

Hourly wages were low for the time put in six days a week. Shifts were twelve hours. Pictured is the check of Ignatz Syaierski.

|

|

To deal with the increasing number of workers, boarding houses were put up near the plant. It was a warm bed for a single man for less than a dollar a week.

|

As workers sent for their wives and children homes became available through the Gary Land Company. Pictured is a house on Ellsworth Street.

|

|

Homes were available on Gary's Eastside as well. This one was on Rhode Island Street.

|

Business took hold throughout the city. Pictured is West Fifth Avenue.

|

|

Fifth and Broadway was the early Steel City's main intersection as businesses moved in.

|

Gary's first City Hall was constructed at Seventh Avenue and Massachusetts Street. It also housed the police and fire departments.

|

|

The YMCA built its facility downtown to see to the needs of the young men.

|

The steel company set aside land for city parks to give families a place to relax.

|

|

For company and business executives the Gary Country Club was developed.

|

Workers were invited to try out for the various company sponsored sports teams.

|

|

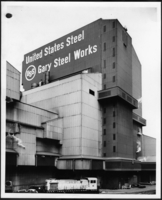

To meet the demands of its customers, U.S. Steel continued to expand and improve the quality of its products. Pictured is the Continuous Caster in 1967.

|

What once was an area of dunes and swamps, U.S. Steel became the largest producer of steel in North America. The lakefront changed from sand to steel.

|